Overview

There are many options working with plastic depending on the work piece trying to be created and the material being used.

The Dyson Centre has several piece of equipment that can be used to assist in creating a work piece such as the laser cutters, the Vacuum former and hot wire bender.

To assist in deciding what would work for your project here is a flow chart showing the option you have.

Available Plastics

The type of plastic you would use depends on the effect you are trying to create and what the design is to be used for. Below is a list of the plastics that we regularly order into the Dyson Centre (up on request).

PLA

PLA (Polyester called Polylactic Acid or Polylactide) is derived from renewable sources such as corn starch. This makes it biodegradable and recyclable therefore easier to dispose of and with no harmful gases given off when used. This plastic is mainly ordered in for uses on the Dyson Centres 3D printers. With a extrusion point of 190°C to 220°C, this plastic is light weight and pliable at (70°C).

ABS

ABS (Acrylonitrile Butadiene Styrene) is made from fossil fuels and therefore will release harmful gasses and like PLA, is recyclable. There are some biodegradable versions now coming on market, but most are not biodegradable. The extruder temperature needs to be at 240°C with the bed temperature at 100°C or higher to create a successful print, the area also need to be ventilated due to the gasses released. This plastic need to be kept 'warm' to ensure the plastic remains pliable as ABS is also a little bit more temperature resistance than PLA.

Both of these above materials are used promarily for 3D printing within the Dyson Centre. Find out more with the link below:

Link to 3D printing

HIPS (High Impact Polystyrene)

HIPS is a versatile, economical and impact-resistant plastic that is easy to machine and fabricate. HIPS is often specified for low strength structural applications when impact resistance, machinability, and low cost are required. It is frequently used machining pre-production prototypes since it has excellent dimensional stability and is easy to fabricate, paint, and glue. This is more commonly used in the Dyson Centre with the Vacuum former.

Link to Vacuum Former

Acrylic Sheet (Perspex)

Sheet acrylic is a versatile and thermosetting plastic with a superior surface finish, flatness and optical properties. It is also easy to break particularly if parts are small or thin. The material does not release harmful gasses when cut/bent via the laser cutter, drill or hot wire bender.

Link to Laser Cutting

Link to Hot Wire Bender

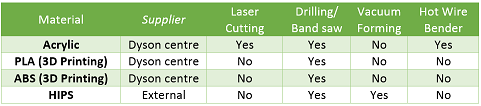

Here is a table with the process that can be used on the plastic listed above, also showing what the Dyson centre stocks.

DRP39, April 2023